Have you heard of Innovative Construction Materials: CARBON FIBER

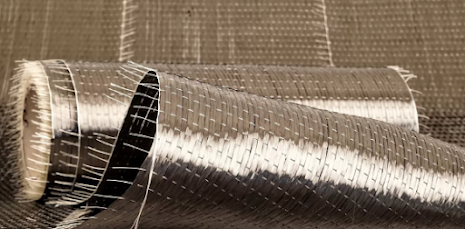

Embarking on a construction project very soon? Woods and metals are slowly substituted by newer construction materials such as carbon fiber. Although this kind of composite material is still in the process of catching up in several hardware in the Philippines, carbon fiber offers numerous advantages in construction, including its suitability for composite profiles in various applications such as window and door systems, high tensile strength, chemical resistance, and low thermal expansion.

Carbon fiber is used in repairing stressed structures like concrete, increasing their capacity and offering quick, corrosion-resistant solutions. Carbon fiber is also increasingly used in bridge construction for its longevity and corrosion resistance. In precast concrete, it replaces steel mesh reinforcement, reducing weight and enhancing durability, making it a versatile material in construction projects.

Advantages of Carbon Fiber in Construction

The demand for composite profiles is on the rise in construction projects worldwide, with pultruded profiles demonstrating their suitability for various applications in both commercial and residential markets, particularly in window and door systems, as well as exterior trim, decking, pergolas, columns, and fencing.

Carbon fibers possess high tensile strength, making them ideal for the construction industry due to their high elastic modulus and fatigue strength.

Carbon fiber-reinforced polymers are known for their chemical resistance, high-temperature tolerance, low thermal expansion, and corrosion resistance, contributing to their growing popularity in civil engineering applications.

Repairing stressed structures, such as reinforced or pre-stressed concrete, often involves the use of externally bonded Fiber Reinforced Polymer composite laminates. This technique enhances the shear and flexural capacity of beams and slabs, increases column confinement, and offers quick installation without significant added weight or corrosion concerns.

Bridge construction is seeing a shift toward carbon fiber for reinforcement and pre-tensioning, as it outlasts steel and remains corrosion-free over time, even in challenging environmental conditions.

In precast concrete production, carbon fiber is replacing traditional steel mesh reinforcement, reducing the weight of wall panels by approximately 40%. Carbon fiber grids strengthen panel faces and can also be used as shear grids to create structurally sound, thermally efficient sandwich wall panels. Additionally, carbon fiber is a superior replacement for steel filaments in fiber concrete and fiber-cement, enhancing the durability of high-loaded floors, roads, and asbestos-free applications without posing inhalation risks.

Comments

Post a Comment